Customer Solutions.

Can’t do, Won’t do.

The requirements and wishes of our customers are both a challenge and an incentive for us. We do not want to supply machines ‘off the shelf’, we want to solve problems!

Our team of highly qualified and motivated constructors and technicians will work with you to develop your individual special solution, perfectly tailored to your needs.

Benefit from our consulting and engineering so that you can manufacture to your wants and needs.

The requirements and wishes of our customers are both a challenge and an incentive for us. We do not want to supply machines ‘off the shelf’, we want to solve problems!

Our team of highly qualified and motivated constructors and technicians will work with you to develop your individual special solution, perfectly tailored to your needs.

Benefit from our consulting and engineering so that you can manufacture to your wants and needs.

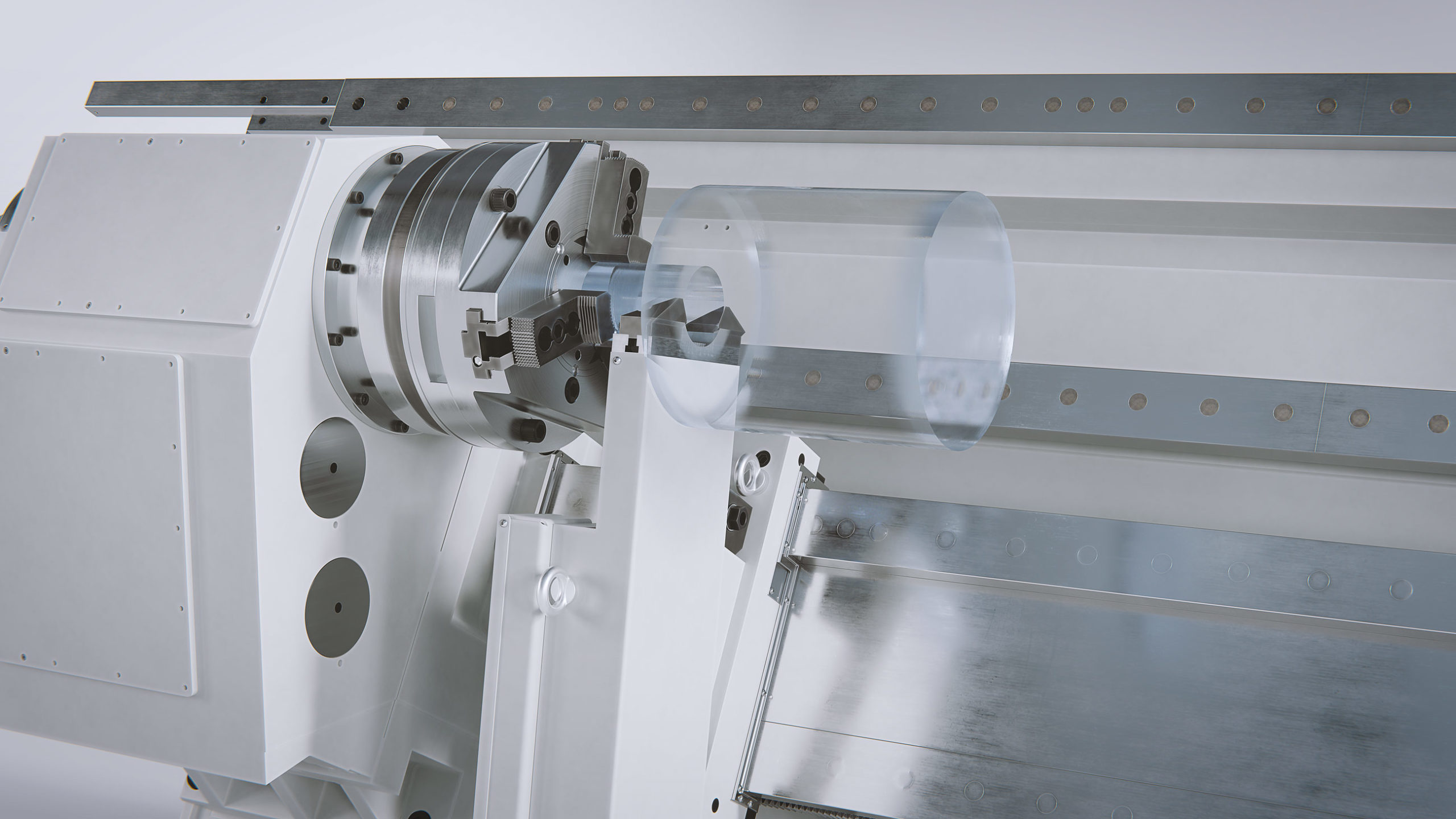

Heynumat inclinded-bed turning lathe

Vertical workpiece deposit

Simple but fast pre-positioning of workpieces when they are inserted into the lathe. The workpiece is picked up via prism and brought into its intended vertical positions. This serves to relieve the operation and protect the machine from falling workpieces.

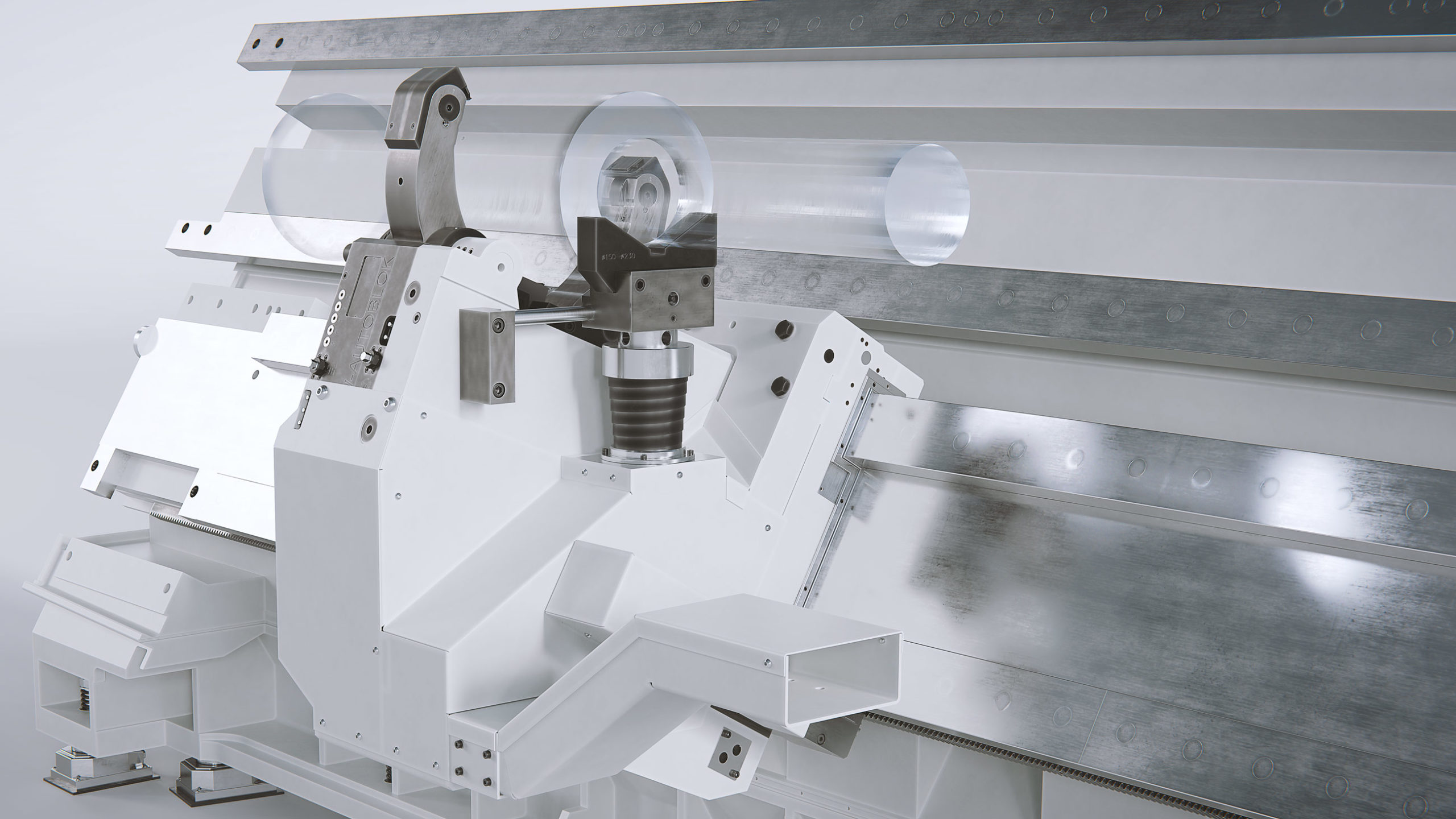

Horizontal workpiece positioning

Simple and fast pre-positioning of workpieces when they are inserted into the lathe. An automatically adjustable intermediate stop, positions the workpiece in their horizontal position. This speeds up the loading process on the machine as well as makes it safer.

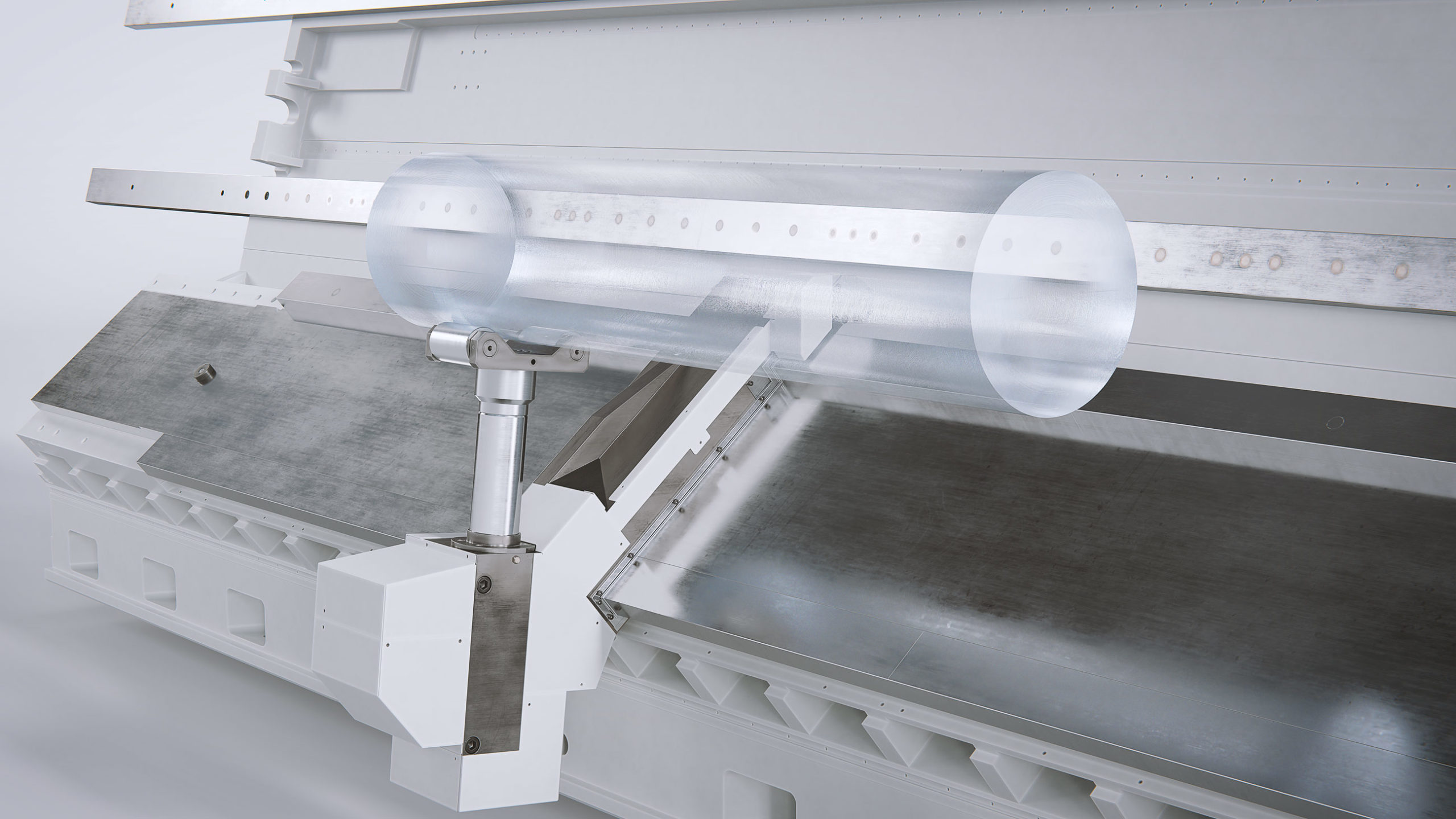

Damping Steady Rest

Positioning of the damping steady rest on the lower bed of the lathe. The hydraulically adjustable support rollers allow the targeted elimination of oscillations and vibrations when machining thin-walled tubes. This leads to higher process reliability and quality.

We look forward to new challenges.