HM46-L2-5000

Heynumat

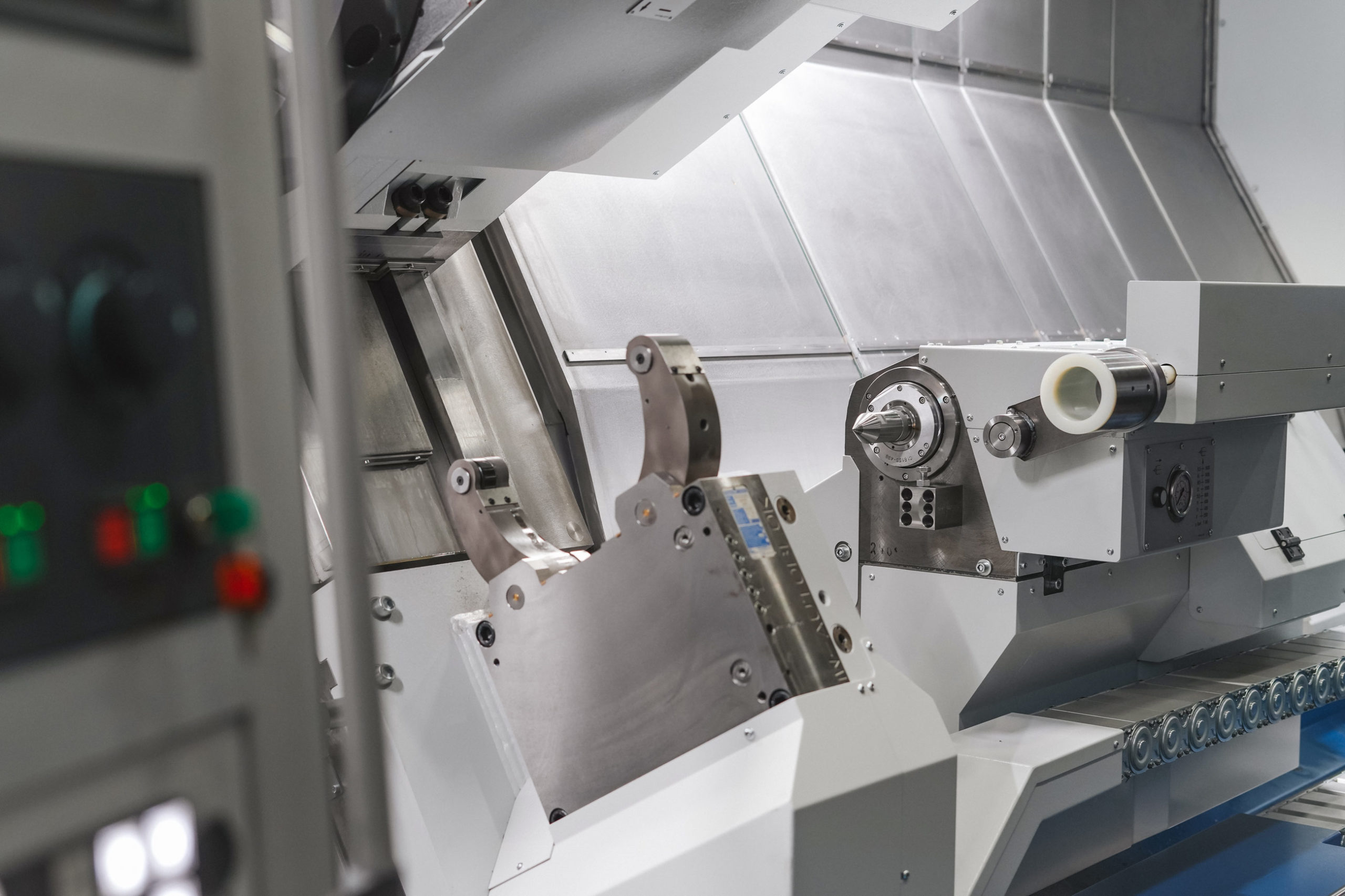

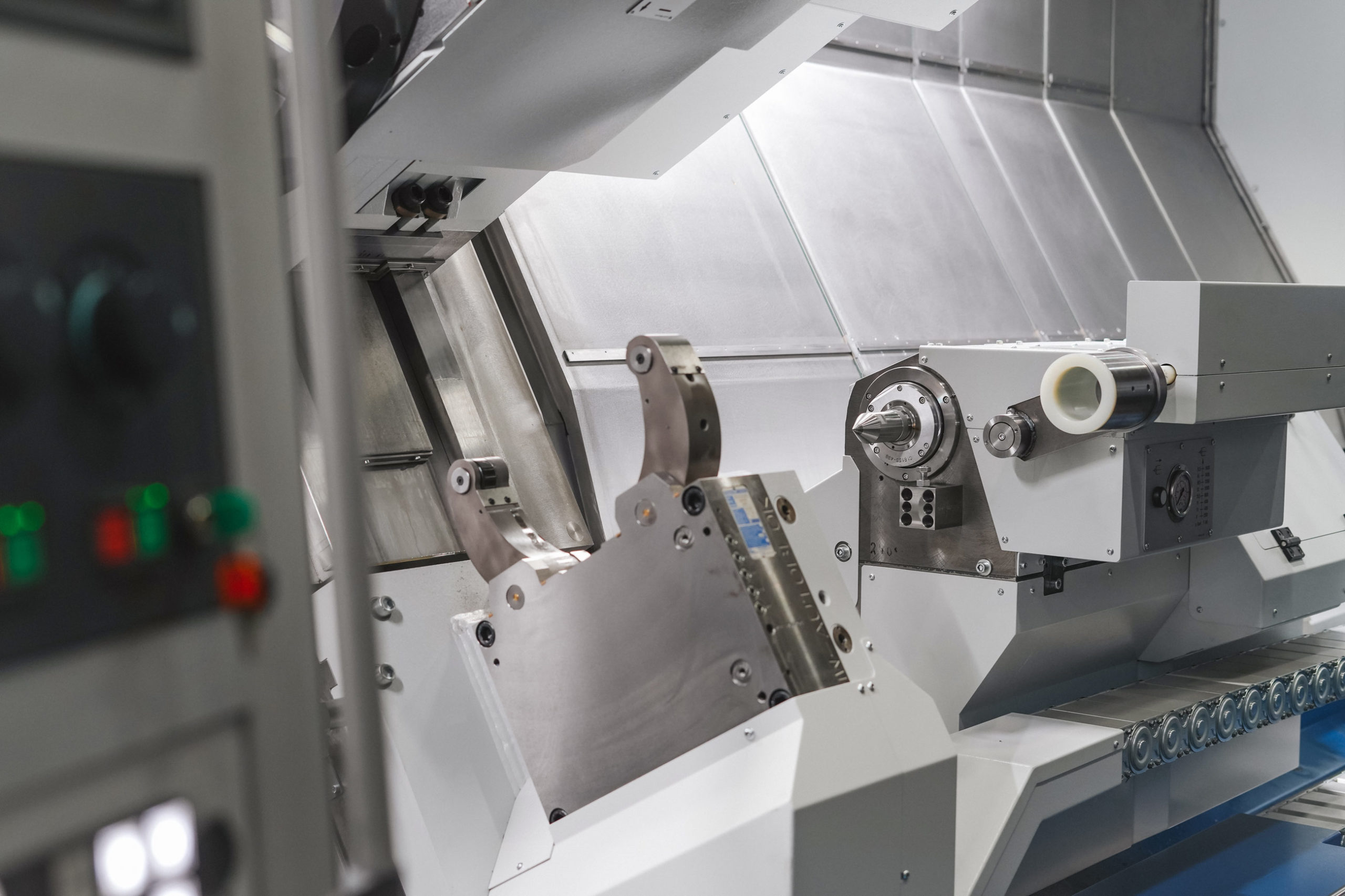

Inclined bed lathe

The Classic.

High-Performance precision machining.

Basics of the Heynumat series

- Standard machine with modular expansion stages

- Stability due to heavily ribbed inclined bed

- High damping behavior due to machine bed made of high-quality gray cast iron

- Large-dimensioned, through-hardened narrow-flat guides in X and Z axes

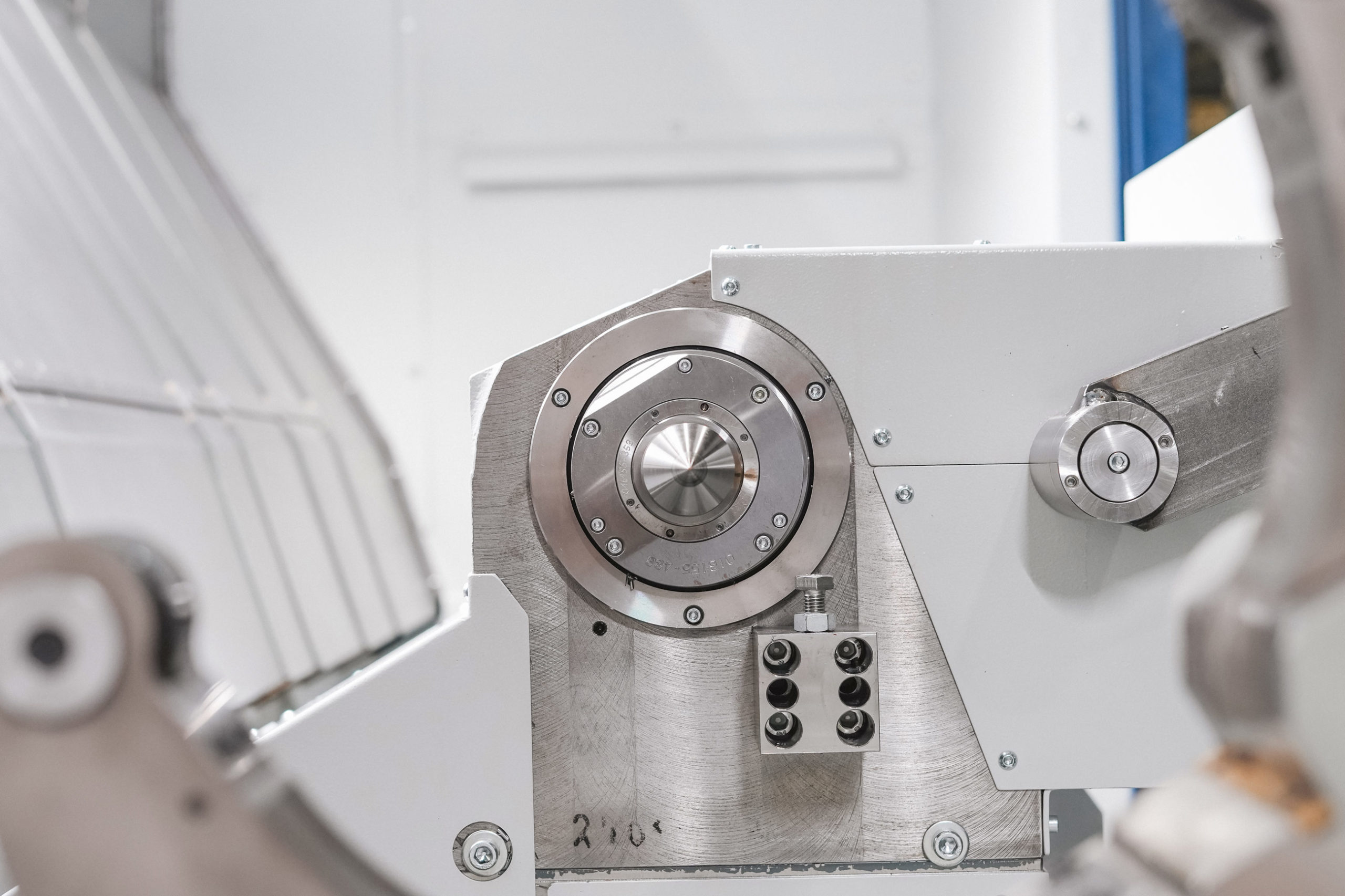

- Combined roller-slide guide for maximum damping and geometric long-term accuracy

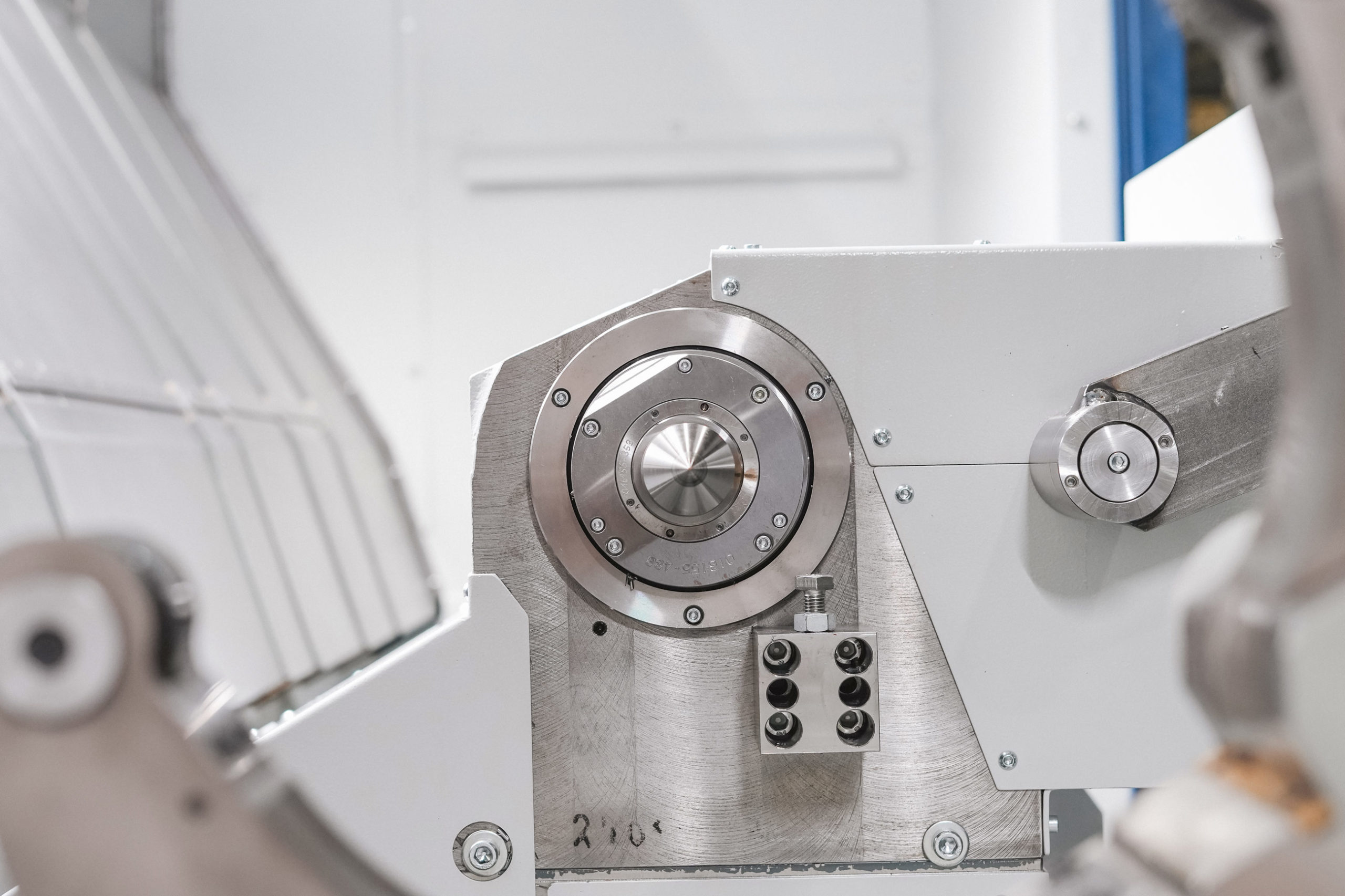

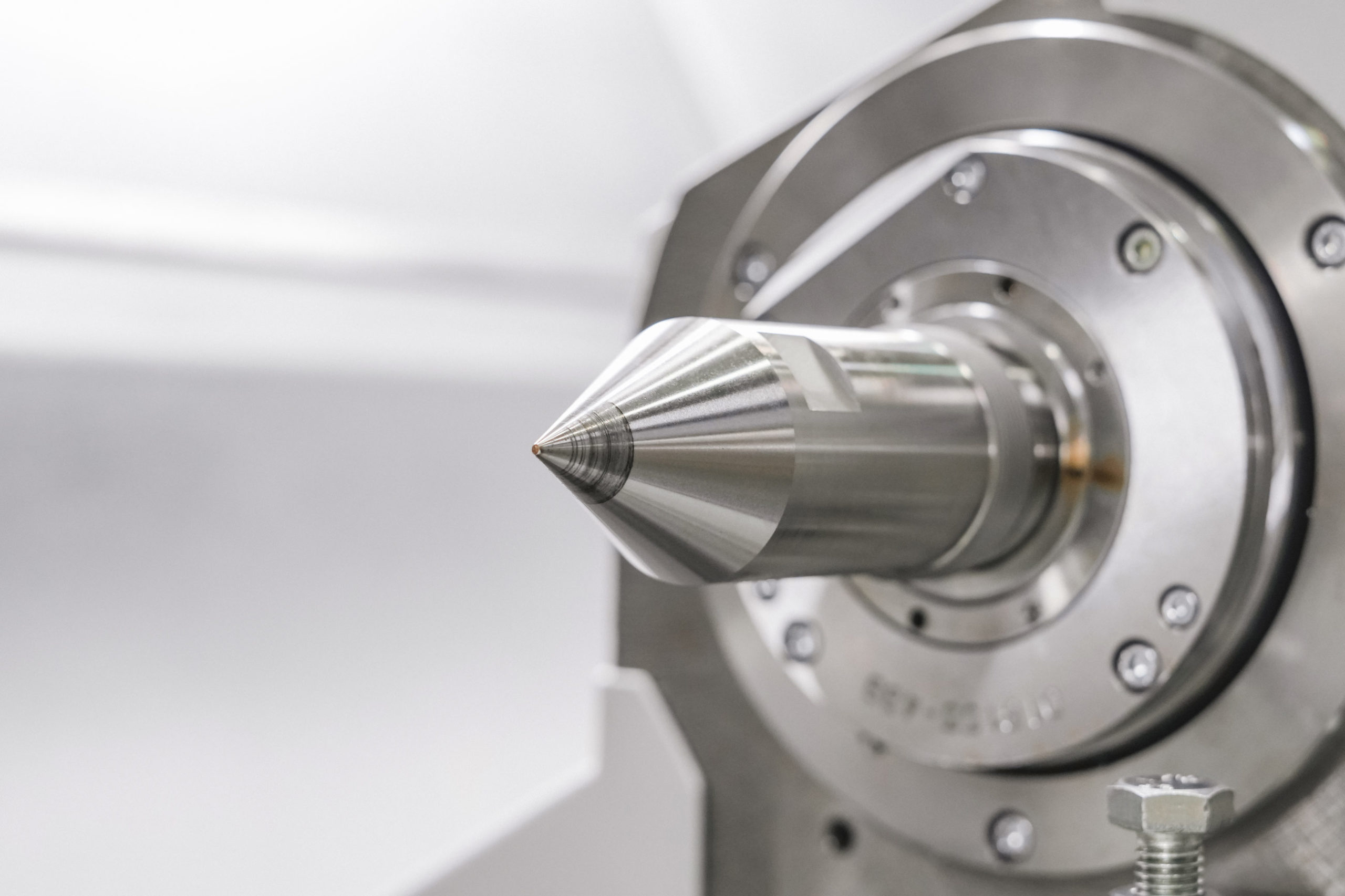

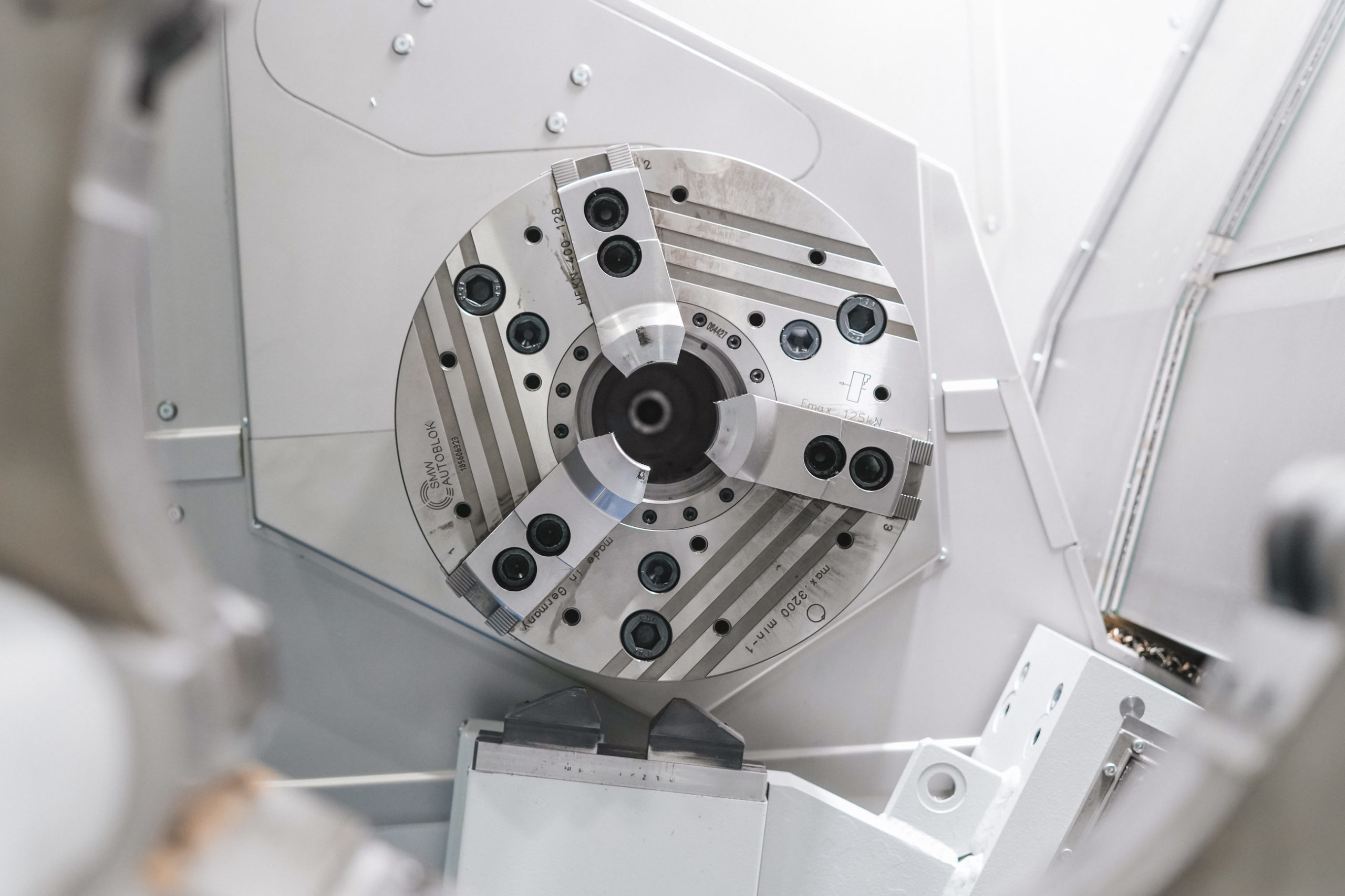

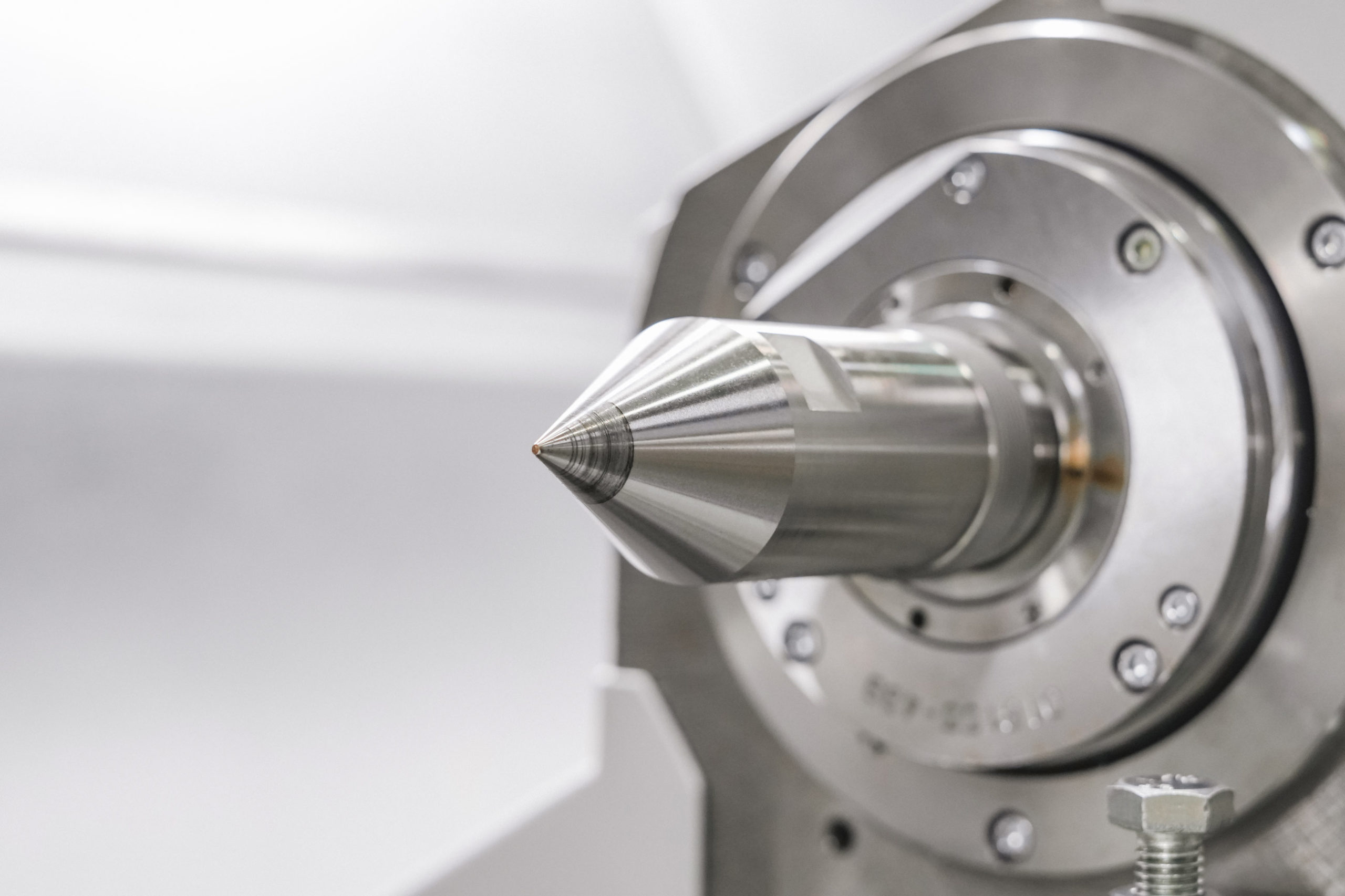

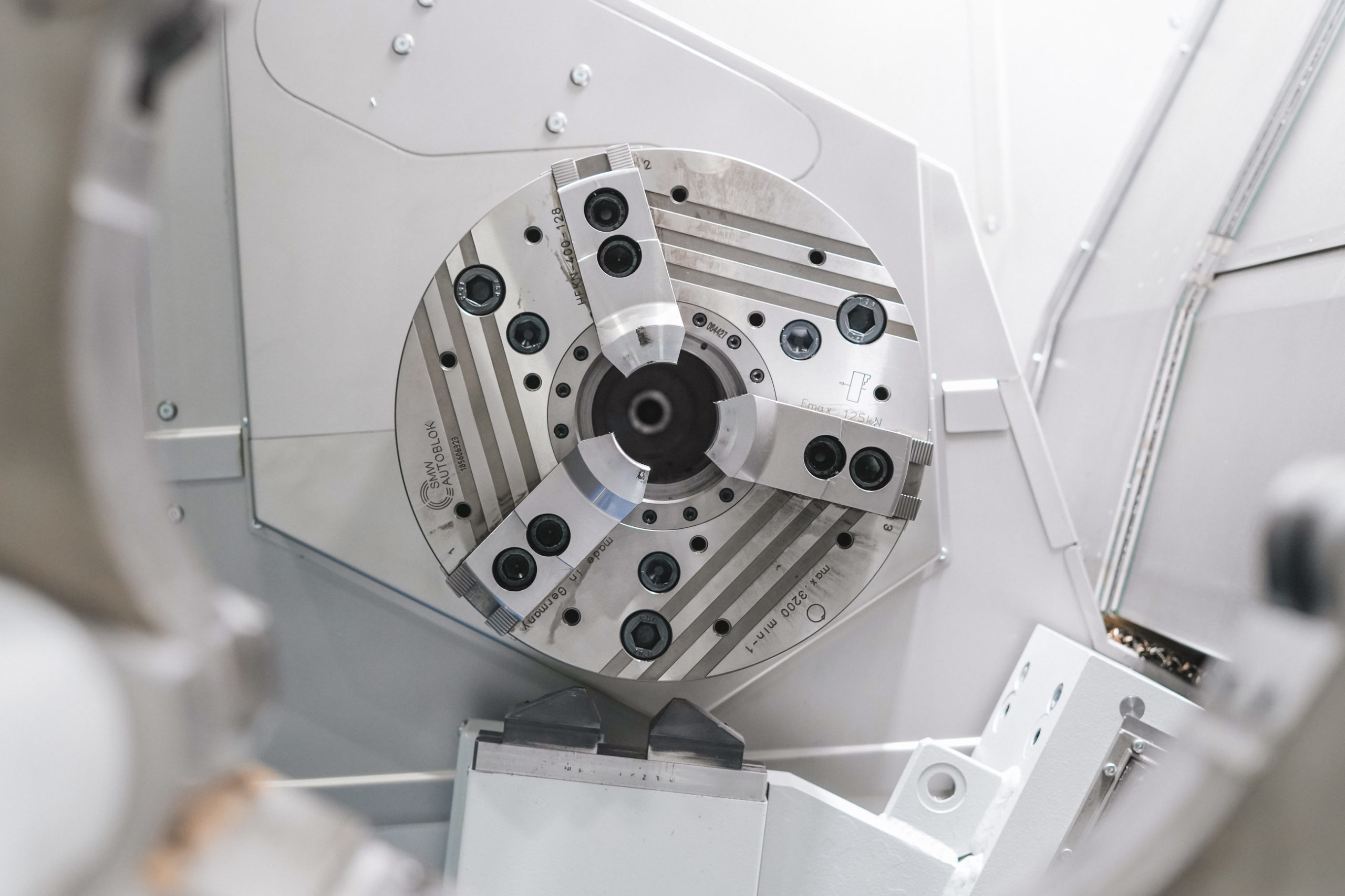

- Headstock with automatic two-stage gearbox

- Single or double slide machining

- Tool turret up to 16 tool positions

- Driven tools

- C-axis

- Y-axis

- Linear measuring system in all axes

- Control: Siemens Sinumerik ONE

- Various standard options available (steady rests, Y-axis, tool measuring system, tool carrier system, counter spindle...)

- Individual equipment variants

Heynumat series performance data

- 2- and 4-axis design

- Nominal length up to 8,000 mm

- Swing diameter up to 1200 mm

- Workpiece weight up to 10.000 kg

- Main spindle power up to 100 KW

- Torques up to 11.000 Nm

- Speed range up to 2.500 revolutions / min

HM46-L2-5000

Slide

Slide

Heynumat Action.